Jan 22, 2026

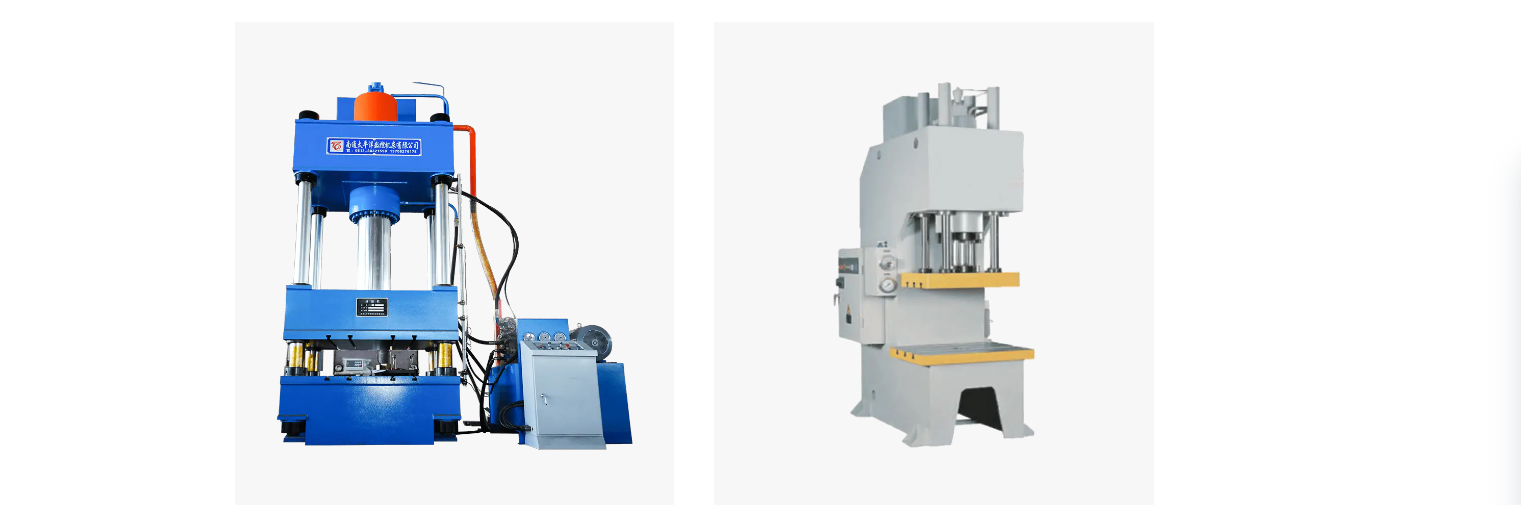

In the world of manufacturing, a hydraulic press machine is one of the most powerful and versatile tools used to shape, mold, and form materials. Whether it's for metalworking, plastic molding, or even car repair, the hydraulic press plays a crucial role in various industries. But what exactly is a hydraulic press machine, how does it work, and why is it so popular? Let’s break it down and answer these questions in simple terms.

Content

A hydraulic press machine is a machine that uses hydraulic force to compress, shape, or mold materials. It works on the principle of Pascal’s law, which states that pressure applied to a confined fluid is transmitted undiminished through the fluid. In simpler terms, the machine uses hydraulic fluid (usually oil) to generate a large amount of force, which is then used to perform tasks like pressing, bending, punching, or forming materials such as metal, rubber, and plastic.

The hydraulic press consists of two main parts: a piston and a cylinder. The piston is connected to a hydraulic fluid reservoir, and when pressure is applied to the fluid, it forces the piston to move, applying immense force to the material being worked on. The press can be controlled manually or automatically, depending on the specific machine and the task at hand.

Hydraulic press machines offer numerous benefits that make them a staple in many manufacturing and industrial applications. Below are some of the key advantages:

One of the main reasons hydraulic press machines are widely used is their ability to generate tremendous amounts of force. Because the hydraulic system uses fluid to transmit pressure, it can create much higher force levels compared to other mechanical methods, such as screw presses or mechanical presses. This makes hydraulic presses ideal for tasks that require a lot of pressure, such as forging, stamping, and forming metals.

Hydraulic presses allow for very precise control of the amount of force applied. Operators can adjust the pressure, stroke length, and speed to meet specific requirements, ensuring that materials are shaped accurately without excess deformation or waste. This level of control is especially useful in industries like automotive, aerospace, and electronics, where precision is key to the final product.

Hydraulic presses are highly versatile machines that can perform a wide range of tasks. From metal forming and shaping to plastic molding, hydraulic presses can be adapted to suit different materials and processes. With the right die or mold, they can perform tasks like punching, bending, embossing, and pressing, making them invaluable in various manufacturing sectors. Whether you're working with thin sheets of metal or thick blocks of rubber, a hydraulic press can handle it all.

Compared to other types of presses, hydraulic press machines are generally more energy-efficient. Since the hydraulic system uses pressurized fluid to transmit force, it requires less energy to produce the same amount of power compared to mechanical presses. Additionally, hydraulic presses can operate at lower speeds without sacrificing performance, which further enhances energy savings in the long run.

Hydraulic presses require relatively low maintenance compared to mechanical presses. With fewer moving parts and no need for regular lubrication of gears, the hydraulic press is more durable and easier to maintain. Regular checks on the hydraulic fluid levels and seals are usually all that’s needed to keep the press running smoothly.

While hydraulic press machines are incredibly useful, there are a few important considerations to keep in mind when using them to ensure safe and efficient operation:

Hydraulic presses need regular maintenance to ensure their optimal performance. This includes checking the hydraulic fluid levels, inspecting the seals, and monitoring the pressure levels. Neglecting regular maintenance can lead to issues such as leaking fluid, reduced pressure, and even complete system failure. It’s essential to follow the manufacturer's guidelines for maintenance and perform routine inspections to avoid downtime and costly repairs.

Due to the immense pressure and force that hydraulic presses generate, safety is a top priority. Always wear appropriate safety gear, such as gloves, goggles, and steel-toed boots, to protect yourself from any accidents. Make sure the machine is properly set up and that all safety features, such as emergency stop buttons and guards, are in place and functioning correctly. Additionally, never place hands or any body parts near the press while it is in operation.

Different materials require different levels of pressure and types of force. For example, metal may require more force to mold or bend than plastic. Before using a hydraulic press, ensure that the material you are working with is compatible with the machine’s capabilities. Using the wrong material or applying too much pressure can cause damage to both the machine and the material. Always check the specifications and adjust the machine settings accordingly to avoid mistakes.

The dies or molds used in a hydraulic press must be properly aligned and secured before use. Misalignment can result in uneven pressure, leading to defects in the final product. Make sure the die is in good condition, properly fitted, and aligned with the press to ensure accurate results. A poorly set-up die can lead to wastage of materials and poor-quality products.

Hydraulic press machines are powerful, versatile, and efficient tools used across various industries for shaping and molding materials. Whether you're working with metals, plastics, or rubber, these machines can generate the precise force needed for complex tasks with high accuracy and minimal energy consumption. However, like any powerful piece of equipment, they require regular maintenance, proper safety precautions, and careful operation to ensure smooth performance.

If you’re looking for a reliable and efficient machine for your manufacturing process, a hydraulic press machine is definitely worth considering. With its ability to provide immense force, versatility in material handling, and minimal maintenance needs, it’s a staple in industries ranging from automotive to electronics. Just remember to follow proper safety protocols and maintenance guidelines to get the most out of your hydraulic press machine.