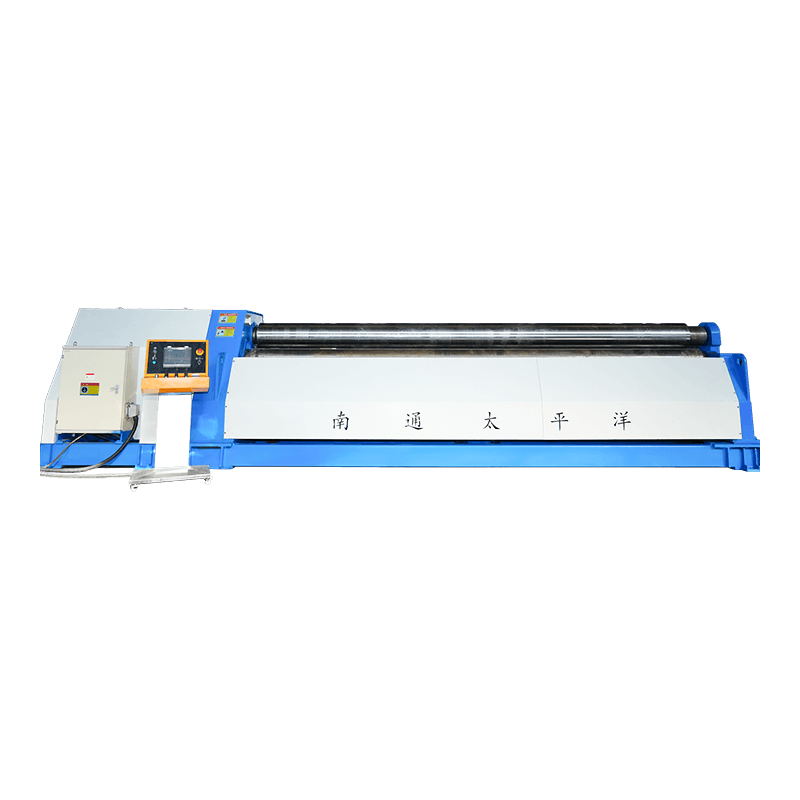

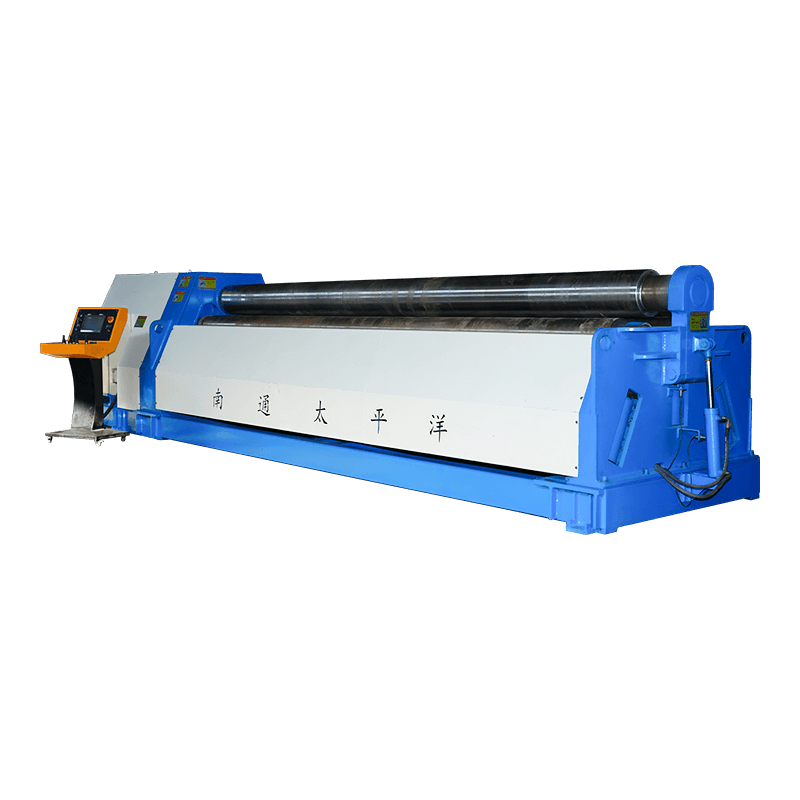

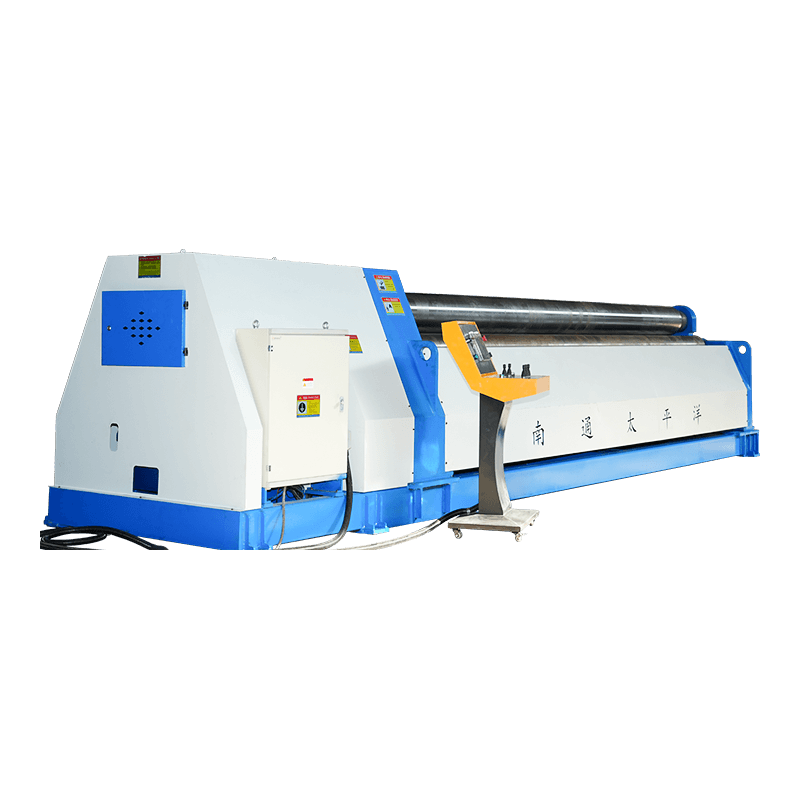

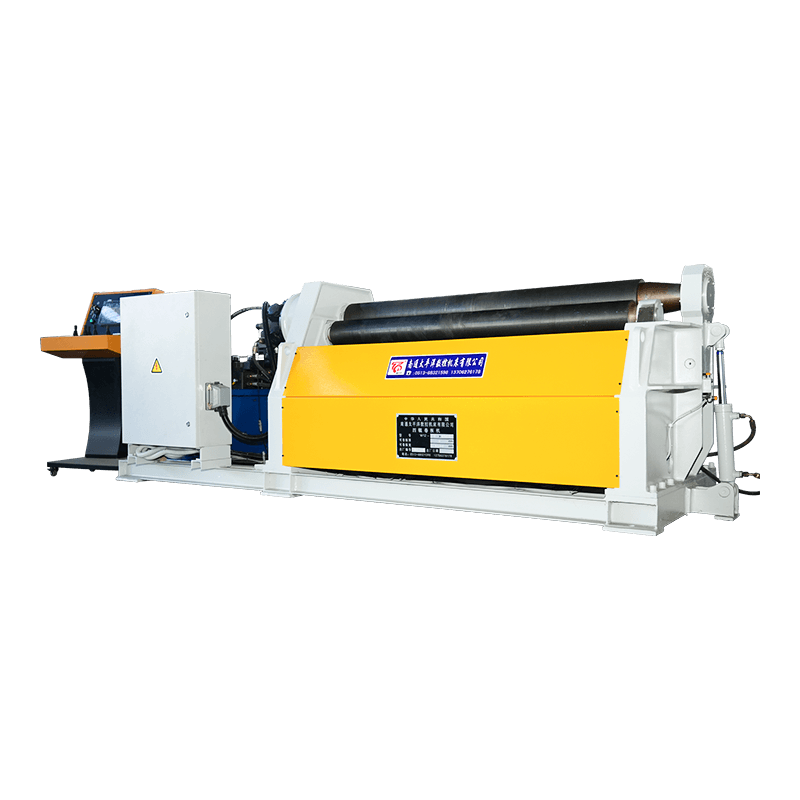

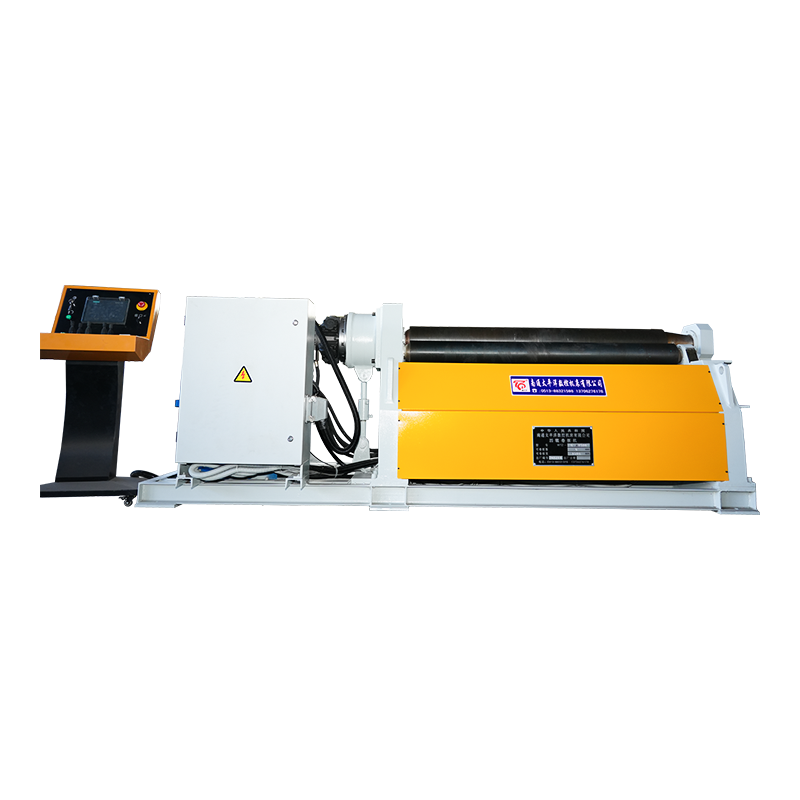

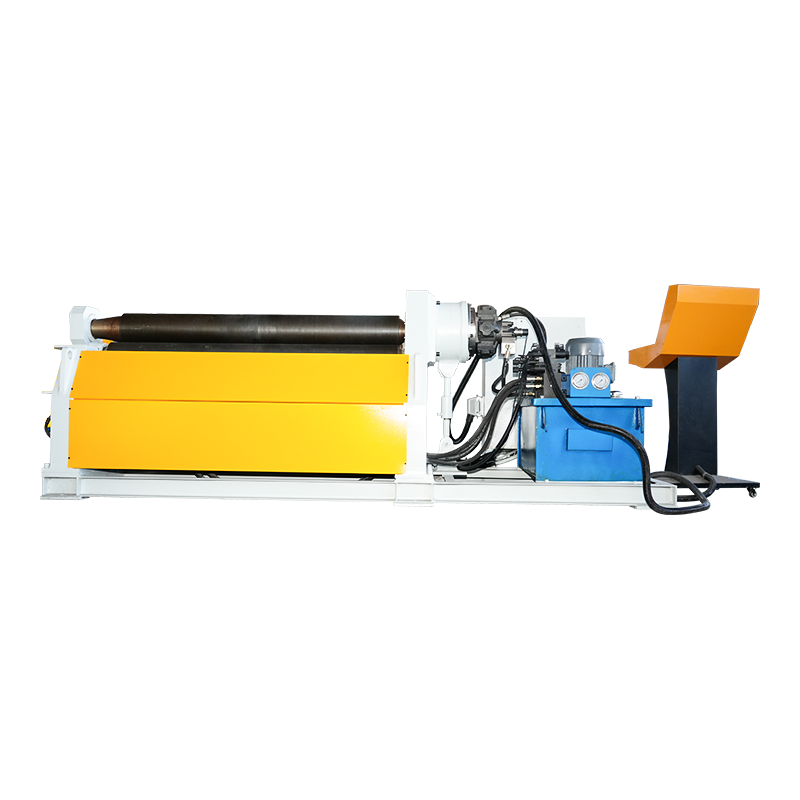

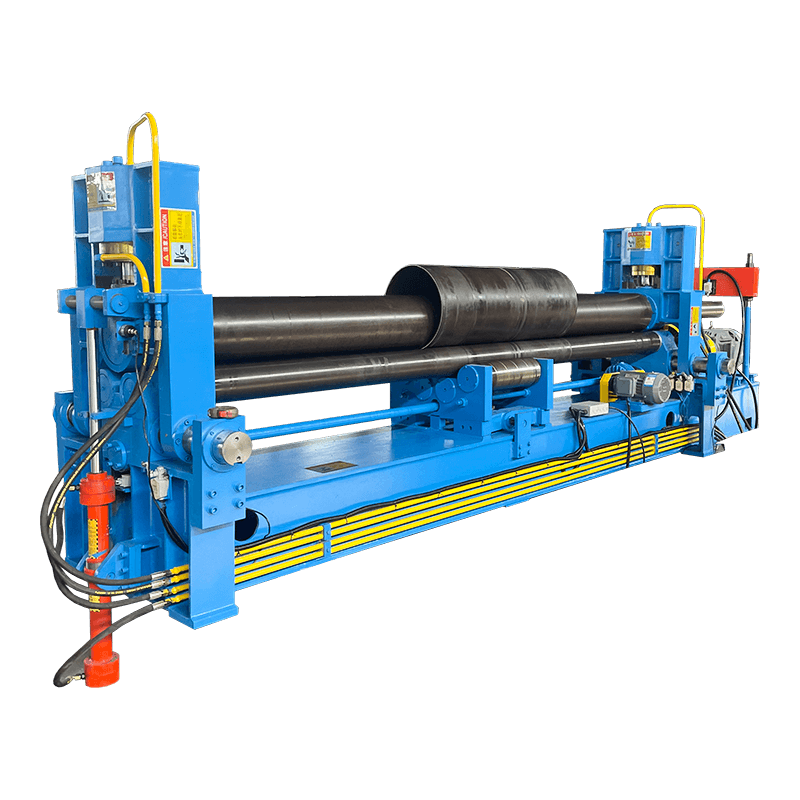

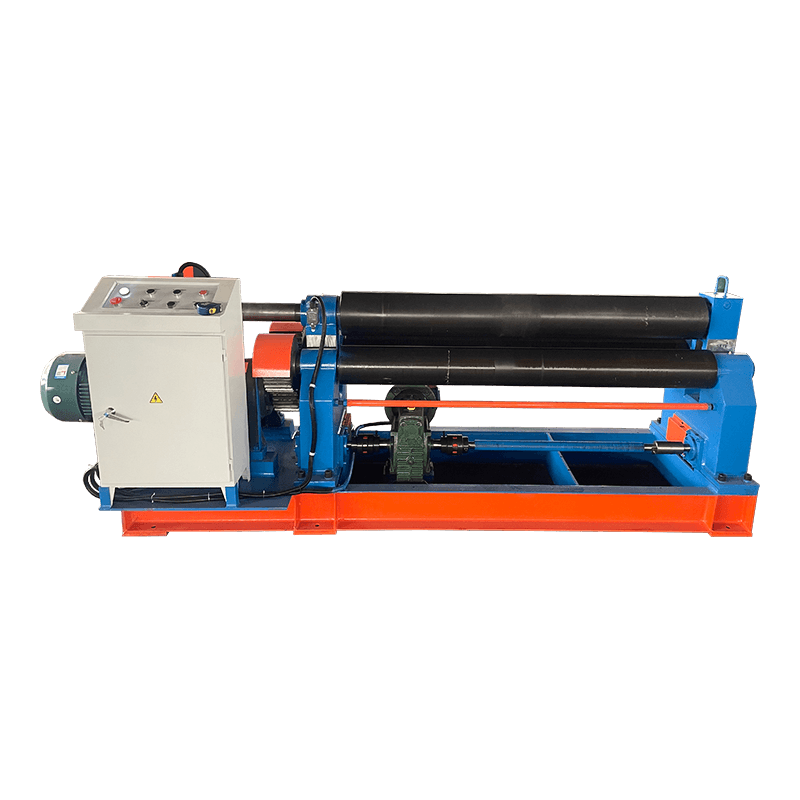

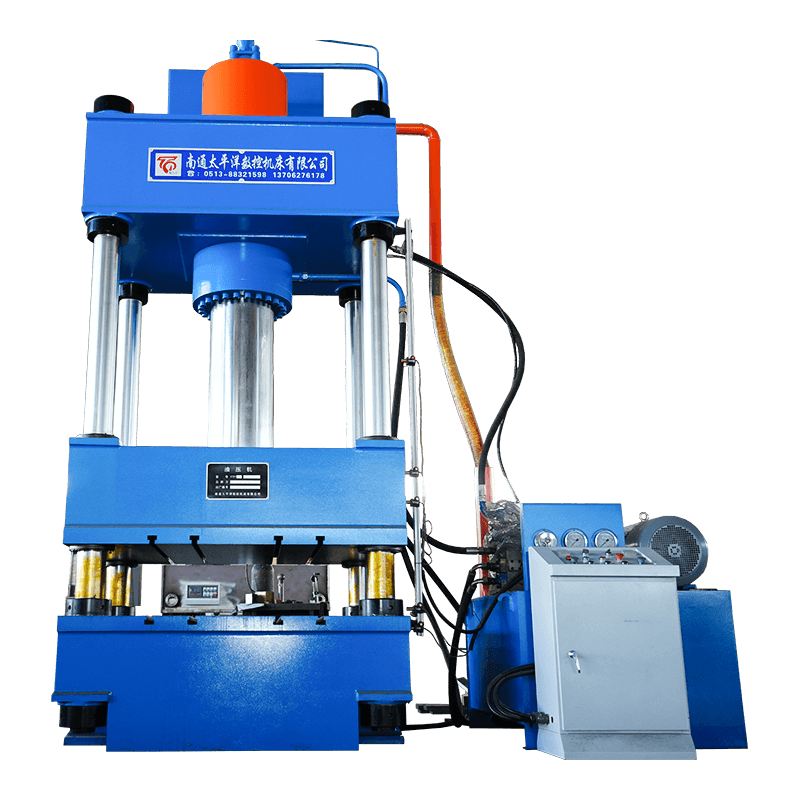

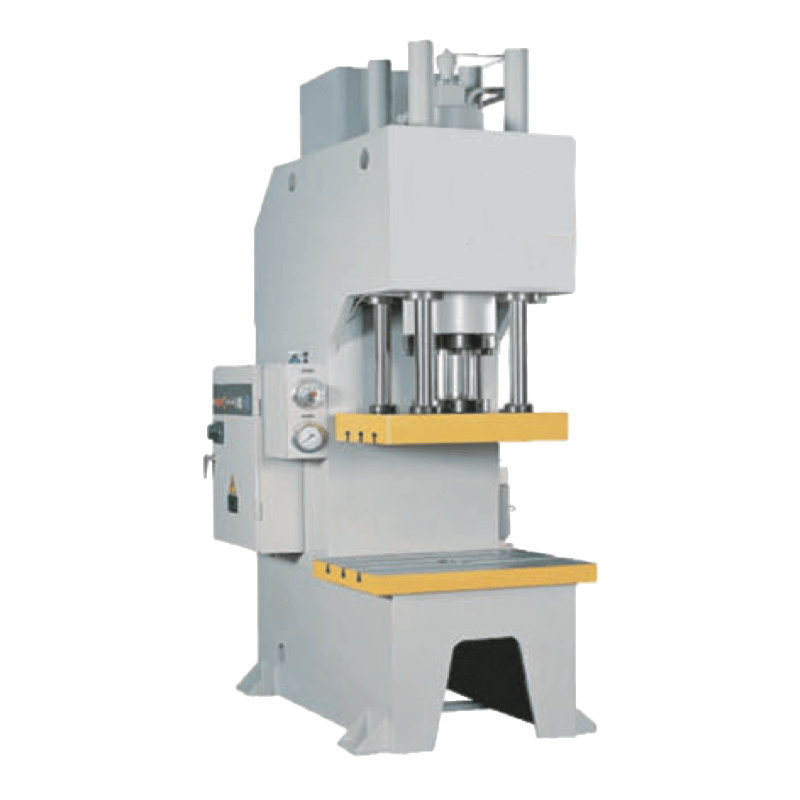

Nantong Pacific CNC Machine Tool Co., Ltd is a key enterprise of national machinery industry, located in Haian Economic and Technological Development Zone, where the environment is beautiful and the traffic is convenient, which facilitates the rapid establishment of communication between enterprises and customers. The enterprise is fully equipped, specializing in the production of shearing machine, bending machine, rolling machine, hydraulic press, punching machine and other products, widely used in: light industry, aviation, shipbuilding, metallurgy, instrumentation, electrical appliances, stainless steel products, construction and decoration industry. Our products sell well both at home and abroad.

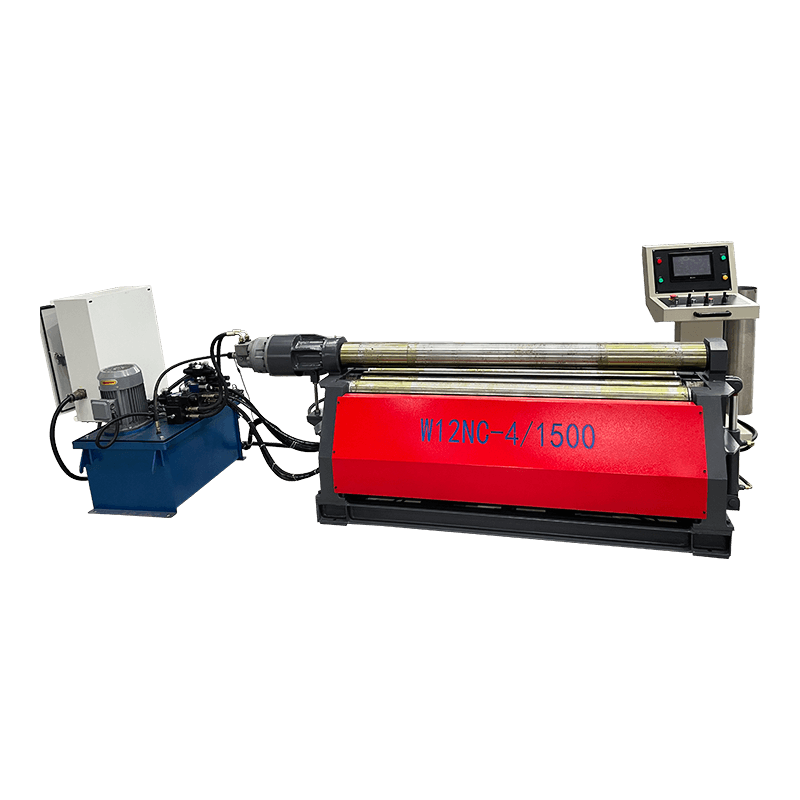

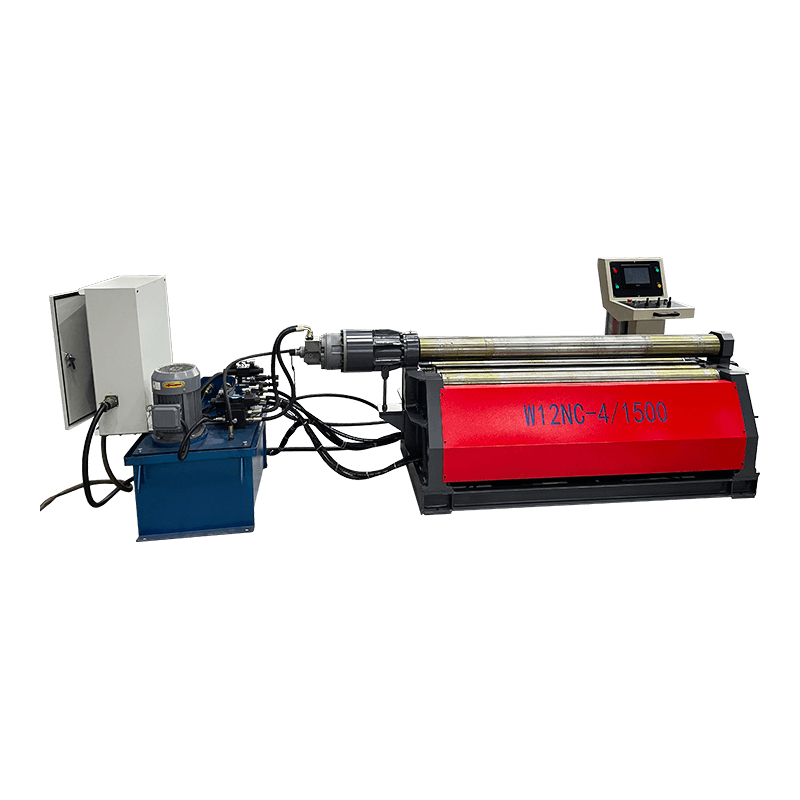

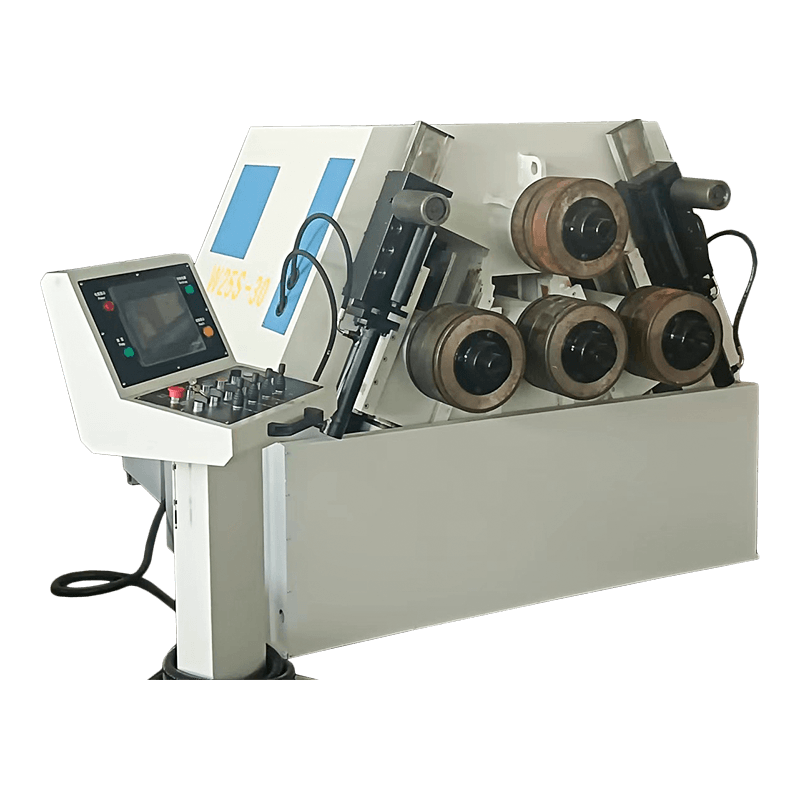

As a professional China 4 Roller Rolling Bending Machine Manufacturers and W12 Series 4-Rollers Rolling Machine Company, The company now has the ability to design, develop and manufacture standard series products and non-standard equipment. Products sell well throughout the country, a large number of exports to Southeast Asia, Europe, the United States and the Middle East. The company covers an area of more than 20,000 square meters, with a group of engineers and technicians with rich professional knowledge, production and testing equipment is complete. Over the years, has been committed to the research and innovation of forging machine tools, the product sales and after-sales service is sparing no effort, has in Beijing, Tianjin, Shenyang, Shandong, Zhejiang, Guangzhou, Shanghai, Hangzhou, Chengdu, Xi 'an and Jiangsu area established a more perfect set of pre-sale, sale, after-sales service in one of the branches, do our best to meet the needs of domestic and foreign customers.

In today's world full of hope and opportunities, Pacific Machine Tools and our customers go hand in hand for common development.